DREDGING 101

WHY DO WE DREDGE THE BAY?

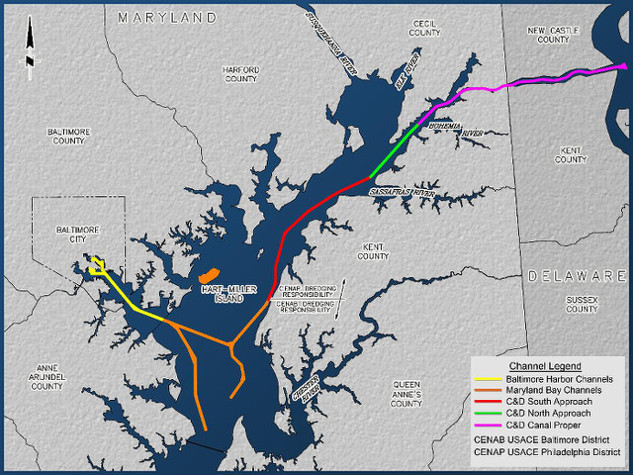

Large cargo ships require passage through shallow portions of the Chesapeake Bay to access the Port of Baltimore, so Federal shipping channels are dredged by CENAP.

Channels are regularly maintained via dredging. Sediment dredged from Federal channels is currently being placed in facilities owned by MDOT MPA, such as the Masonville or Cox Creek DMCF or the Paul S. Sarbanes Ecosystem Restoration Project at Poplar Island.

Sediment built up in the channels comes from multiple sources, including settling of upland soil suspended in the water, slumping of the sidewalls of the existing channel, resuspension from ships passing through the channel, and resuspension from wind and tide actions.

DIFFERENT WAYS TO DREDGE

Mechanical dredging involves removing sediment with machinery, usually with a bucket type of mechanical dredges such as a dipper dredges or clam shell dredges. Mechanical dredges are capable of removing hard-packed materials or debris. They can work in tight areas and are efficient when large barges are used for long-haul disposal to the placement location. Mechanical dredges have difficulty retaining loose, fine materials, do not dredge continuously like pipeline dredges, and may need added controls when handling contaminated sediments. To see a video of a mechanical dredging operation, click HERE.

Hydraulic dredging includes the use of a pump, usually barge mounted, to move material in a slurry (mixture of sediment and water) via a pipeline.

The two primary types of hydraulic dredges are the cutterhead pipeline dredge and the self-propelled hopper dredge. Advantages of cutterhead pipeline dredges include their ability to excavate most materials, to pump material directly to a disposal site without use of a barge for hauling, to dredge almost continuously, and to reduce the likelihood of cross contamination (when dealing with contaminated sediments). However, cutterhead pipeline dredges have limited capability in rough weather; have difficulty with coarse sand in swift currents; and, for the most part, are not self-propelled. In addition, the necessary pipeline can be an obstruction to navigation and, when handling debris in sediment, the removal efficiency is diminished.

Self-propelled hopper dredges are seagoing vessels that can operate in rough water and move quickly to a jobsite under their own power. They carry the dredged material within the hold of the ship and once the ship is full, dredging stops and the ship travels to an in-water disposal site, where the dredged material is discharged through the bottom of the ship. The dredging operation does not interfere with other navigational traffic. Work progresses quickly and is economical for long-haul distances. Hopper dredges are limited to work in deep waters, but they cannot dredge continuously. Excavation is less precise than with other dredges, and this dredge type has difficulty dredging steep banks and consolidated materials. To see a video of a hydraulic dredging operation, click HERE.

WHAT'S IN DREDGED MATERIAL?

- Sediment consists of clay, silt, and sand.

- Geologic formations in the region, as well as human activities, affect the character is the sediment in different locations.

- Industrial activity, agriculture, and urban development have all left their mark.

- In general, sediment dredged from the bottom of the Bay does not have pollutants at the levels that could cause human or environmental harm.

As part of the dredging process, CENAP samples sediment from the shipping channels for chemical analysis every three years for upland placement of dredged material. Using recent CENAP sediment data as a starting point, the Maryland Environmental Service (MES) reviewed data on Upper Bay dredged sediment quality, looking at sediment data from:

- Upper Bay channels

- The Pearce Creek DMCF

- Sediments placed in open-water sites (now prohibited)

This data was compared to MDE soil cleanup standards for both residential and non-residential sites, background soils data for Maryland, and Baltimore Harbor dredged material.

The comparison showed:

- Dredged sediment from the Upper Chesapeake Bay was not significantly more contaminated than reference soil, and was less contaminated than Baltimore Harbor channel sediments.

- Almost all samples contained arsenic and chromium levels higher than MDE standards – even background soils.

Background concentrations alone do not determine MDE standards; a risk-based standard is used. As a result, it is common for undisturbed, natural soils to contain metals above MDE soil standards.

1. Shipping navigation channels need to be maintained to allow for access to the Port of Baltimore.

2. Using a clamshell bucket, material is dredged from a navigation channel and placed into a scow.

3. Once the scow is filled with dredged material, a tugboat moves the scow to the appropriate placement site.

4. Water is mixed into the scow to create a slurry, which is hydraulically pumped into the facility. The slurry ratio is approximately 80% water to 20% solids.

5. Hydraulic unloading is the quickest way to unload dredged material. Excess water used during this process is discharged from the facility via a spillway, once it meets permit-required water quality limits.

6. The dredged material then dries out and consolidates, increasing surface capacity and creating a more stable surface.

Information courtesy of the U.S. Army Corps of Engineers

Back to Top